2205 Stainless Steel Machinability

This grade offers higher resistance to corrosion.

2205 stainless steel machinability. As an example machining of 2205 is around 20 slower than for 304. The grade is characterized by. Sanmac 2205 is a machinability improved version of the duplex austenitic ferritic stainless steel sandvik saf 2205. High resistance to stress corrosion cracking scc in chloride bearing environments high resistance to stress corrosion cracking scc in environments containing hydrogen sulphide.

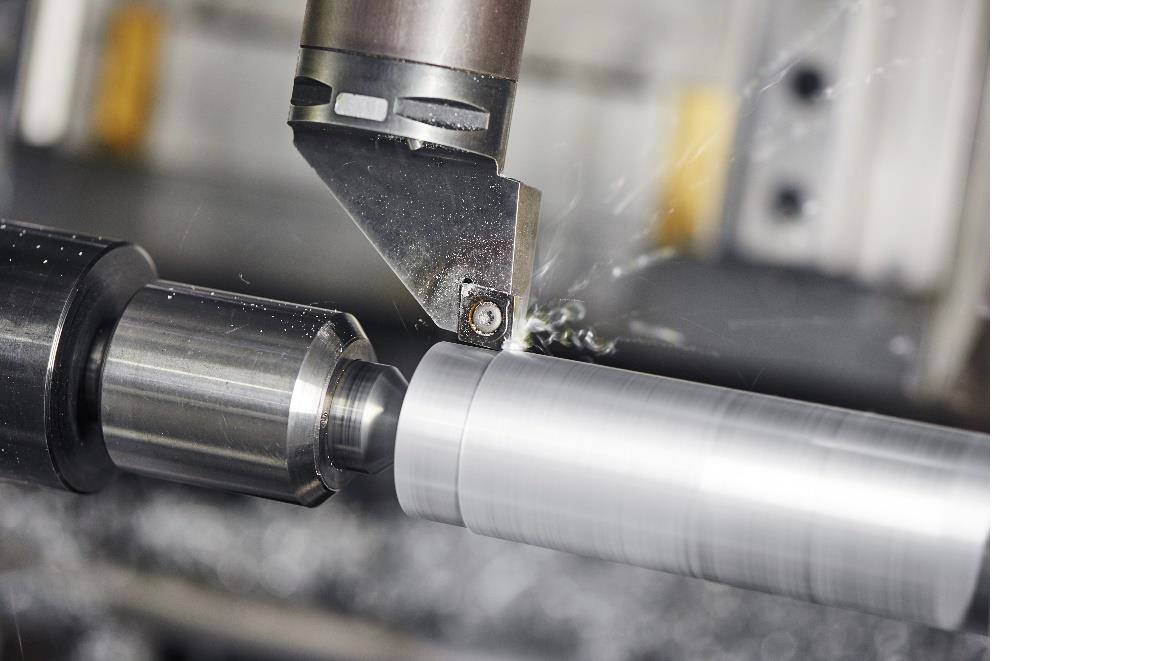

These precautions are necessary to avoid cross contamination of stainless steel by easily corroded metals that may discolour the surface of the fabricated product. Although machinable the high strengths of duplex stainless steels makes machining difficult. Introduction duplex 2205 stainless steel both ferritic and austenitic is used extensively in applications that require good corrosion resistance and strength. The machined surface becomes harder at the same time as tool life decreases.

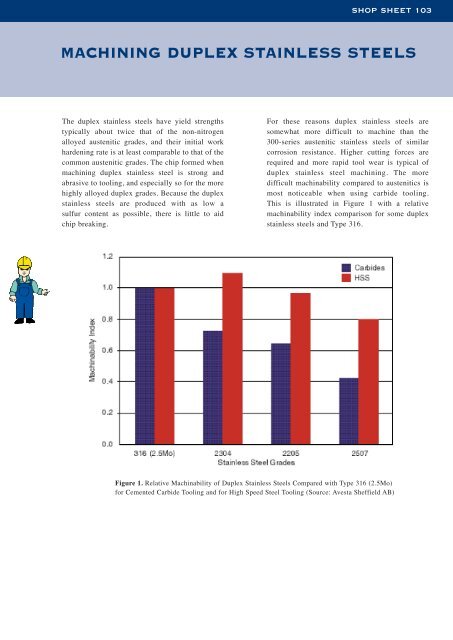

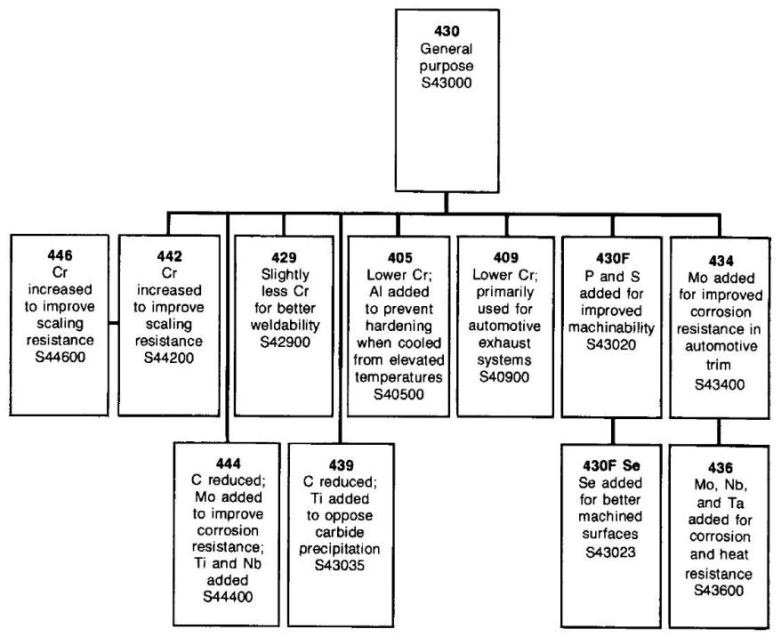

Stainless steels and type 316. Guidelines for machining duplex stainless steels the guidelines for machining below are generally applicable to all stainless steels but following them is especially important for duplex stainless. Machinability duplex 2205 is somewhat more difficult to machine than the 300 series austenitic stainless steels. Alloy 2205 uns s32305 s31803 is a 22 chromium 3 molybdenum 5 6 nickel nitrogen alloyed duplex stainless steel plate with high general localized and stress corrosion resistance properties in addition to high strength and excellent impact toughness.

Saf duplex 2205 stainless steel heat treatment recommended annealing temperature for duplex 2205 stainless steel is 1040 1900 f cooling from the annealing temperature must be rapid water quenching is preferred but it must also meet the limits of deformation. In all machining that involves cutting austenitic and duplex stainless steels work hardening is more pronounced than in carbon steel or ferritic and martensitic stainless steels. The s31803 grade stainless steel has undergone a number of modifications resulting in uns s32205 and was endorsed in the year 1996. Higher cutting forces are required and more rapid tool wear is typical.

.gif)