303 Stainless Steel Microstructure

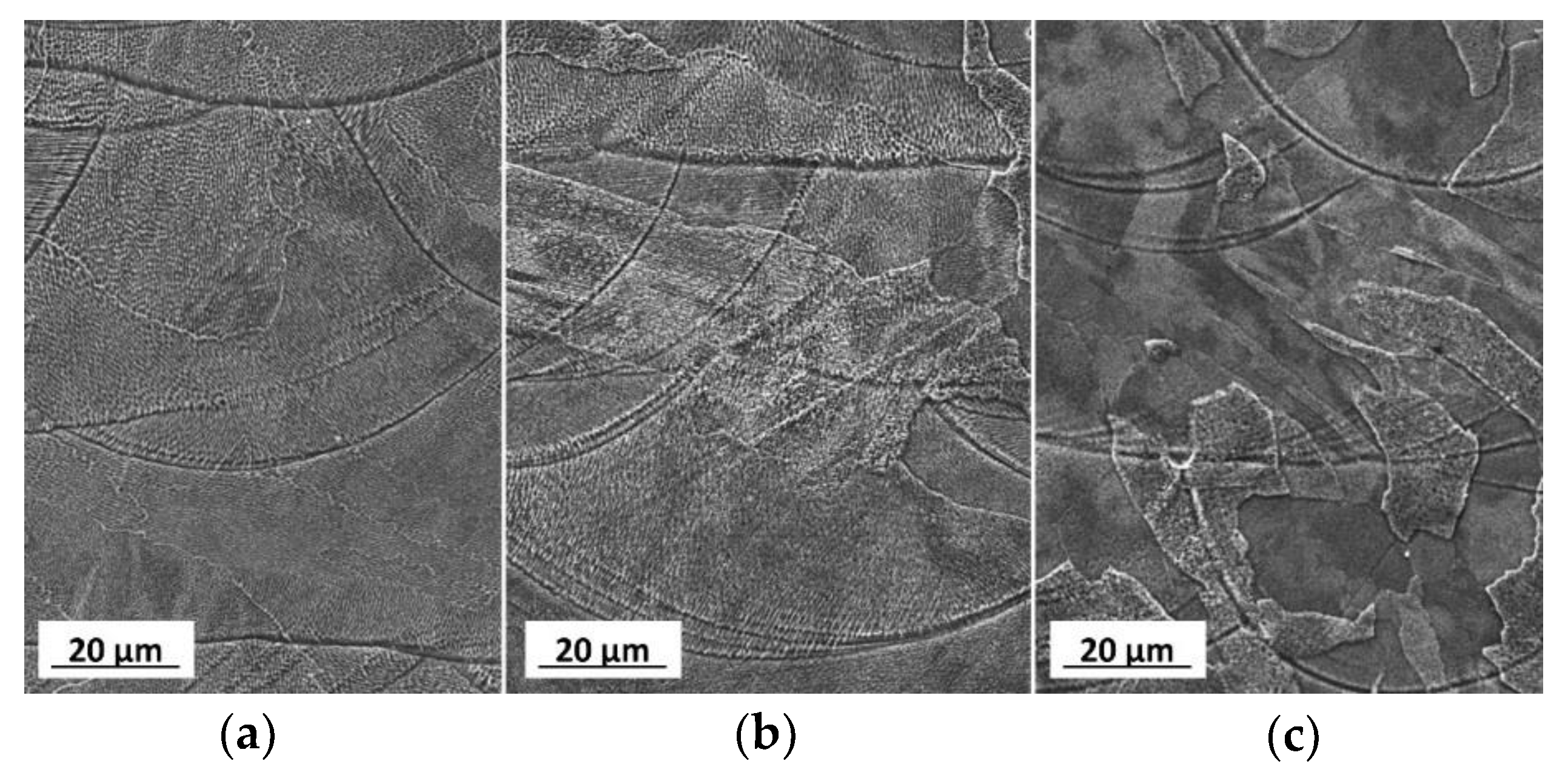

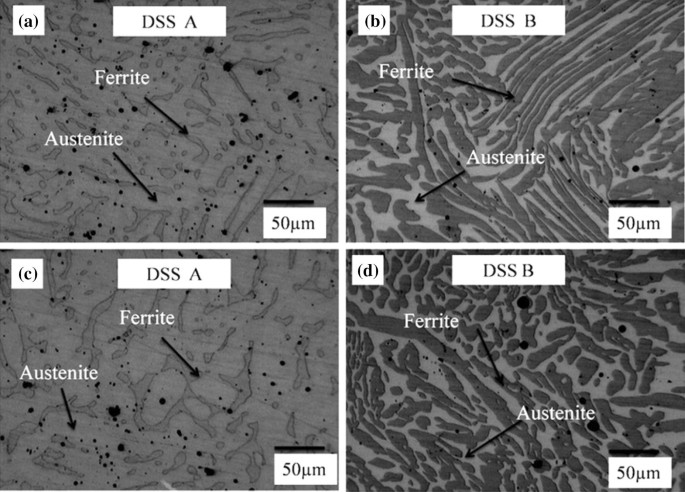

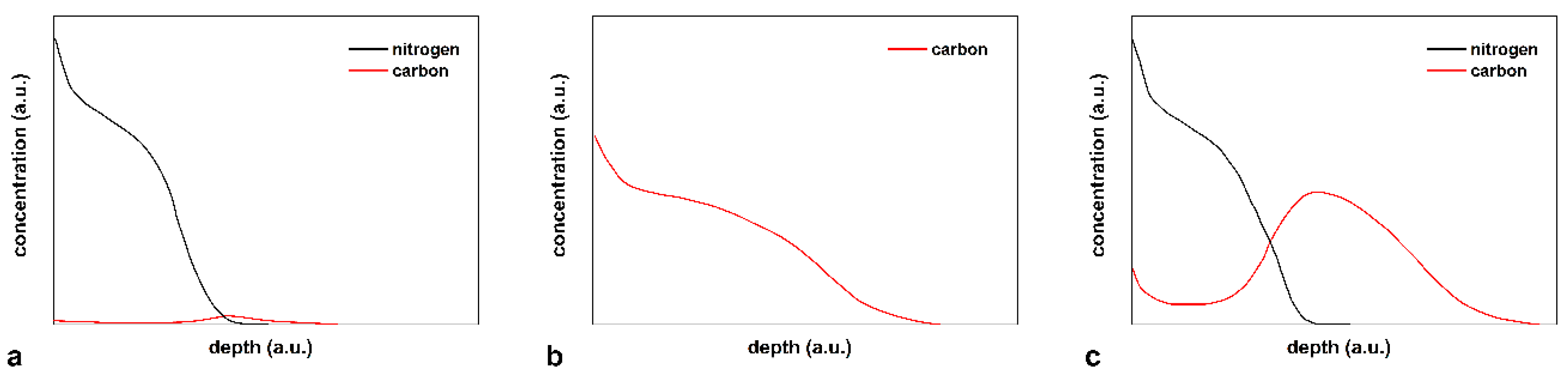

Here the microstructure of a duplex stainless steel slab 1 4362 produced by continuous casting has been investigated by optical microscopy scanning electron microscopy ebsd and eds.

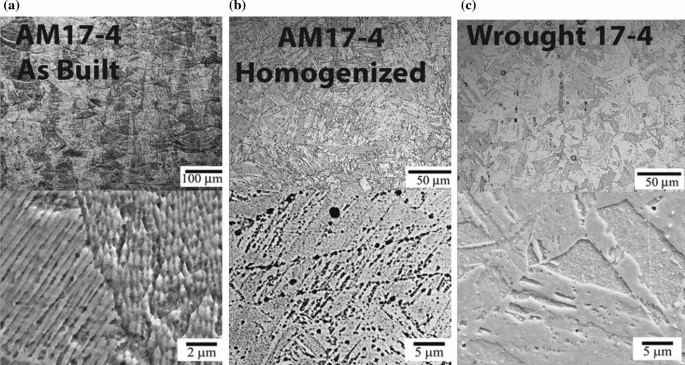

303 stainless steel microstructure. Microstructure texture and mechanical property analysis of gas metal arc welded aisi 304 austenitic stainless steel march 2014 journal of materials engineering and performance 24 3 1125 1139. However corrosion on ss is reported largely at welds or adjacent areas. Easy to machine 303 stainless steel widely used for fabricating fittings and fasteners 303 stainless steel machines quickly without sticking to cutting tools. Austenitic or 300 series stainless steels typically have higher chrome as well as a significant amount of nickel e g.

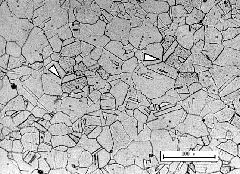

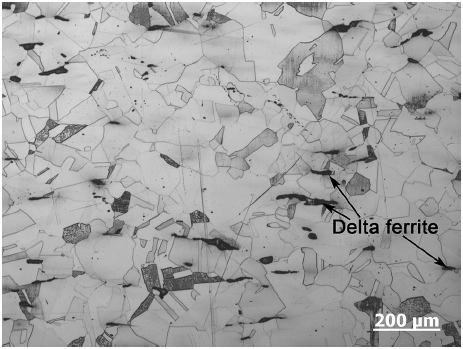

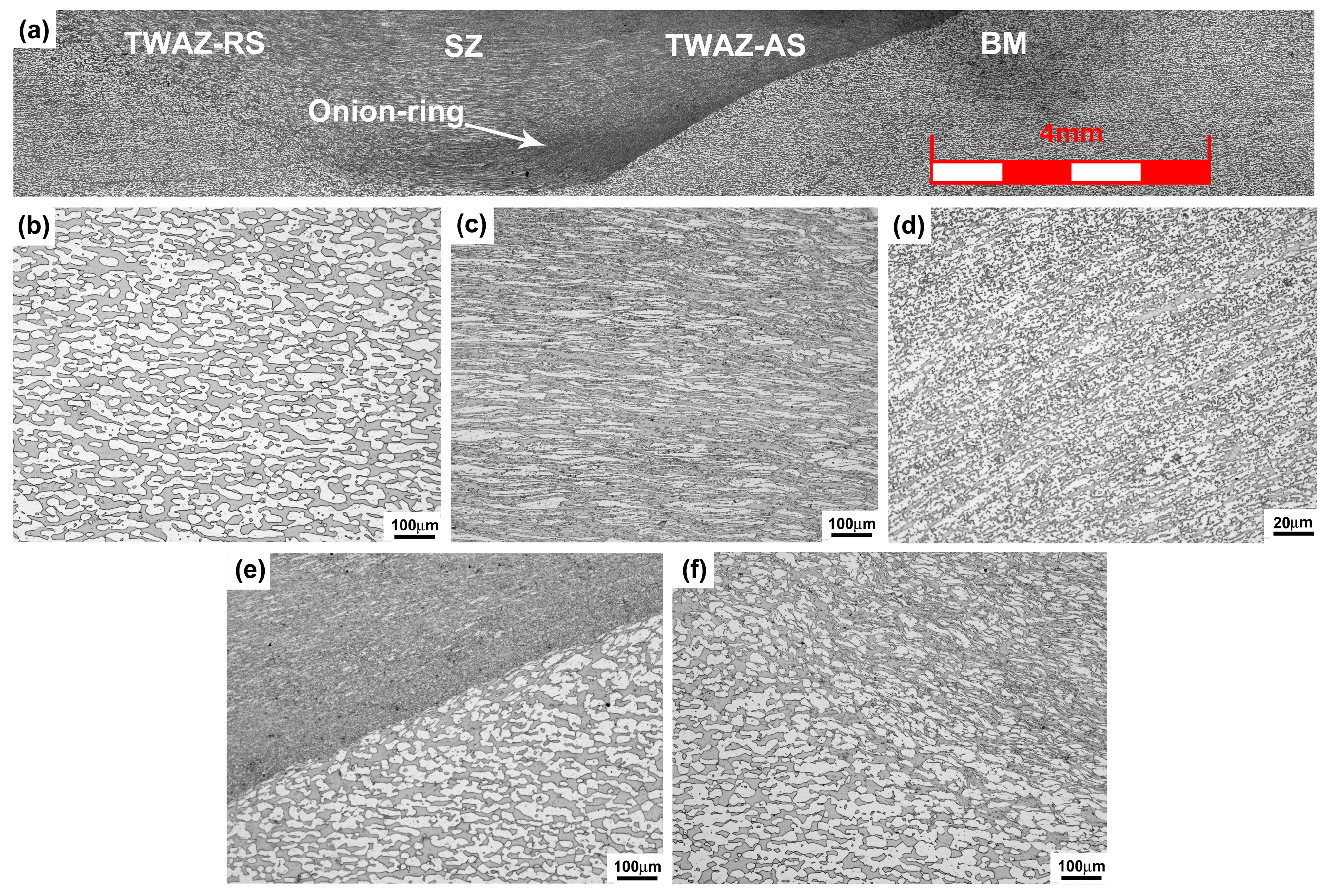

Stainless steels contain iron as the main element and cr in amounts ranging from 10 5 to 30. Among wrought stainless steels the composition of aisi 303 stainless steel is notable for containing comparatively high amounts of nickel ni and chromium cr. The macrostructure can be divided into 3 types. The slab showed different macrostructures through the thickness.

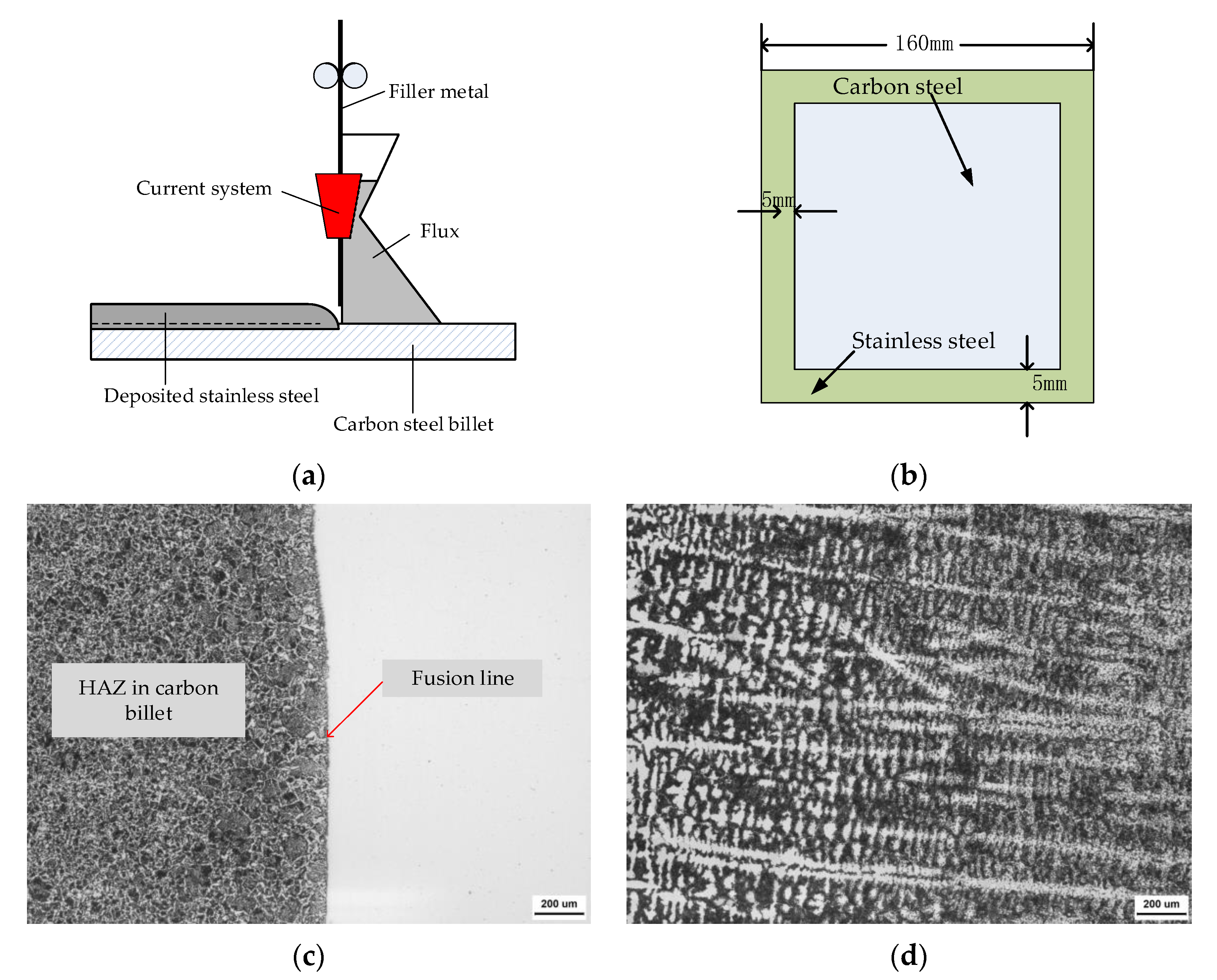

In addition it has a beneficial effect on mechanical properties and certain types of corrosion. Reliable metallurgical bonding was achieved between weld zone and 304 stainless steel. The feasibility of cocrfeni 100 x cu x high entropy alloy filler metal for laser welding between tc4 titanium alloy and 304 stainless steel is investigated. Aisi type 304 l stainless steel ss is a widely used material in industry due to its strength and resistance to corrosion.

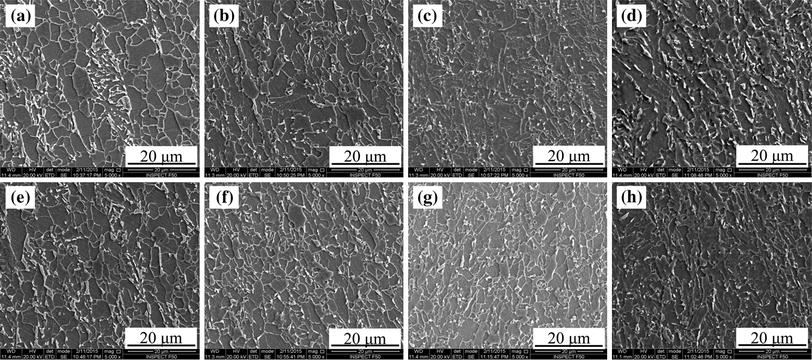

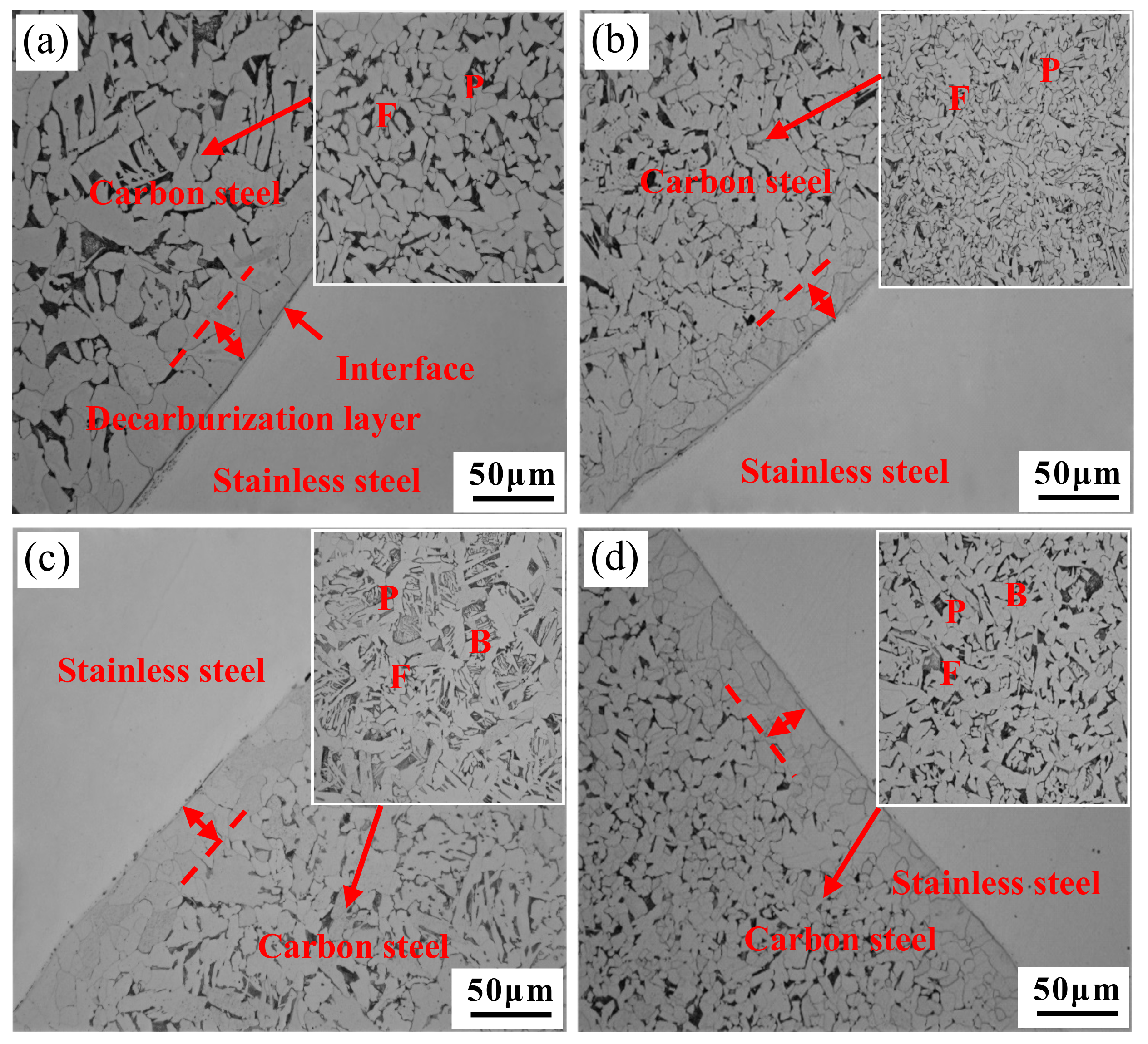

Microstructure and corrosion behavior of dissimilar welds between austenitic stainless steel aisi 304 and ferritic stainless steel aisi 430 were investigated. 304 stainless steel 18 chrome 8 nickel which makes them harder to etch. Metallographic stainless steel etchants etching stainless steels can be somewhat difficult due to the anti corrosive nature of stainless steel. Fine equiaxed columnar and coarse equiaxed grains.

On the other hand microstructure stability is one of the most important requirements for assigning the proper mechanical and or corrosion properties to an austenitic stainless steels asss. The weld zone consisted of ductile fcc solid solution phase and cu rich phase which segregated at the grain boundary of fcc phases. Keywords ferritic stainless steel microstructure mig welding electrode mechanical properties introduction stainless steels are iron base alloys containing at least 10 5 cr.