308l Welding Rod Specifications

308l welding wire and rod applications pulp and paper mills stainless pipe and tubing bakery and kitchen equipment housings and impellers.

308l welding rod specifications. For all stock availability contact sales. Alloy er 308 308l is a stainless steel tig mig and sub arc wire used for welding. Return to main welding page. Other types and sizes are.

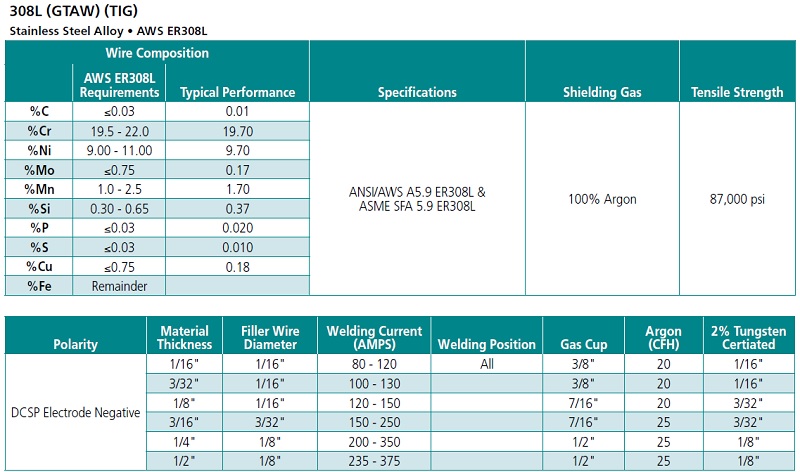

Er308l 308l contains an average 03 carbon producing a weld deposit with good resistance against intergranular corrosion caused by carbide precipitation. It is particularly used to perform submerged arc welding of grade 304 stainless steel. Specifications aws 5 9 asme sfa 5 9 aws er 308 308l uns s30883. Lincoln er308 308l from lincoln electric is designed for use on base metals of similar composition.

308l 308lsi 316 316l and 316lsi. Available in alloys 308 308l 308lsi 309 309l 316 316l and 316lsi. 308l is commonly used for welding aisi types 304l 308l 321 and 347. 2 lb and 10 lb spools.

Grade 308l stainless steel is a low carbon version of grade 308. 25 pound spools available in all alloys listed above. 308l including er308lsi is predominately used on austenitic stainless steels such as types 301 302 304 305 and cast alloys cf 8 and cf 3. There are also military specifications such as the mil e or r types and federal specifications normally the qq r type and ams specifications.

For high temperature applications such as in the electrical power industry the high carbon 308h electrode provides better creep resistance than does 308l. Harris 308l stainless steel tig welding rod 1 16 x 36 10 lbs. Er308l including er308lsi is predominately used on austenitic stainless steels such as types 301 302 304 305 and cast alloys cf 8 and cf 3 for high temperature applications such as in the electrical power industry the high carbon 308h electrode provides better creep resistance than does 308l. See products listing for available diameters in each of the alloys listed above.

308l is an austenitic stainless steel used to weld base metal of similar composition types such as aisi 201 17 4 mn 202 18 5 mn 205 301 17 7 302 18 8 304 19 9. The particular specification involved should be used for specifying filler metals. Lincoln er308 308l we use cookies to help our website work more effectively and efficiently and to align our services and advertisements to your needs. When should i use 308l 309l or 316l filler metal.

Similar usage as 308 but the 0 04 maximum carbon content increases resistance to intergranular corrosion conforms to aws a5 4.

_-_NSS-308_NO_PRINT_copy_copy-1543971355598.jpg)