309 Welding Rod Settings

Some 308l applications may be substituted with 309l filler metal but 316l or 316 applications generally require molybdenum and 309l contains no molybdenum.

309 welding rod settings. Oh h welding 309 alloy at elevated temperature application and dissimilar metals e310 15 16 dc ac f v oh h welding type 310 and 314 stainless steel where high corrosion and elevated temperatures are required e316 15 16 dc ac f v oh h. Get to running the stick electrode the brand was mc vay or mc kay so long ago i don t recall but that rod laid in like 7018 so well i thought i d been given the wrong electrode. All the common arc welding electrodes used for welding on carbon steel have characteristics that make them better suited for different situations. This is especially true if the welding machine amperage dial is out of calibration or if amperage values setting have been faded worn off.

Figured to totally ball it but what the hey. 2 xxwall 309 tig root and hot 309 stick out. Cg 12 is the cast equivalent of 309. Type 347 stainless steel filler metal is ideal for 347 and 321 base materials because it matches these stabilized grades.

Which arc welding rods should i use. A fancy marketing name for 309 or 312 stainless tig rod. The welder would routinely tig weld them with super missile weld rod. I worked a job once where simple carbon steel fixtures where fabricated daily.

Test results for mechanical properties deposit or electrode composition and diffusible hydrogen levels were obtained from a weld produced and tested according to prescribed standards and should not be assumed to be the expected results in a particular application or weldment. Used for welding similar alloys in wrought or cast form. And at times welding dissimilar steels conforms to aws a5 4. Occasionally used for welding type 304 and similar base metals when severe corrosion conditions exist.

Excalibur 309 309l 15 16 17 welding positions. Ease of use easier to use products through auto settings and better visibility. The fast freeze rods have a strong arc force that helps burn off surface impurities. A circular or side to side motion can be used to build up weld or because of the light flux coating these rods can be stepped.

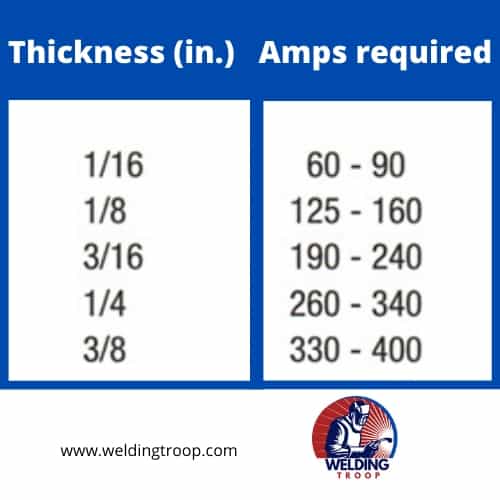

Technique for setting amperage for stick welding.