314 Stainless Steel Corrosion Resistance

Stainless steel chemical compatibility chart.

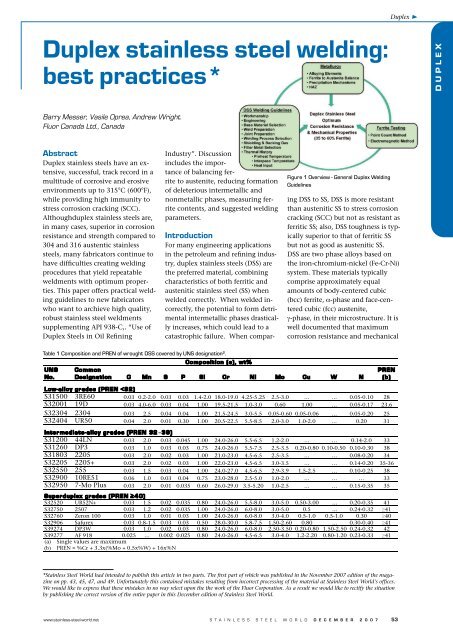

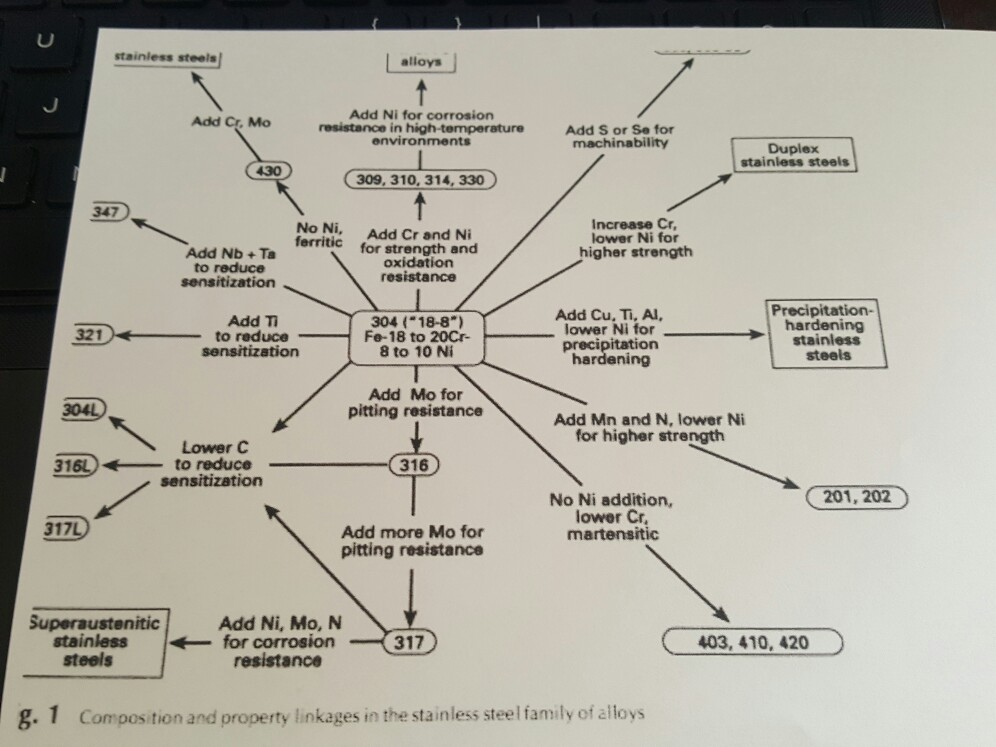

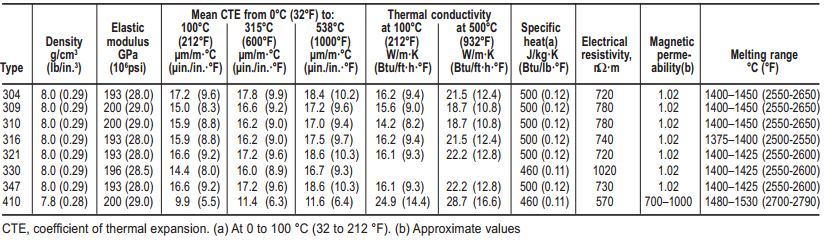

314 stainless steel corrosion resistance. Ss316 has a 0 08 max carbon content while ss316l uns s31603 only has a maximum 0 03 carbon content. Stainless steel must have at least 10 5 chromium in order for the passive layer to form. Both steels are durable and provide excellent resistance to corrosion and rust. 304 stainless steel is the most common form of stainless steel used around the world due to excellent corrosion resistance and value.

That durability makes 304 easy to sanitize and therefore ideal for kitchen and food applications. 304 stainless steel is the most versatile and widely used austenitic stainless steel in the world due to its corrosion resistance. Many a manufacturer has ordered a stainless steel part or basket only to find that their stainless steel has started to show signs of rust and or other problems within a few days or. Let s start with a basic rule of thumb which says the higher the chromium levels contained within the stainless steel the more corrosion resistant the product.

The more chromium that is added the more stable the passive layer becomes and the better the corrosion resistance. This is collated information from various sources but is of limited quality. Ferritic stainless steels possess a ferrite microstructure like carbon steel which is a body centered cubic crystal structure and contain between 10 5 and 27 chromium with little or no or no. 304 can withstand corrosion from most oxidizing acids.

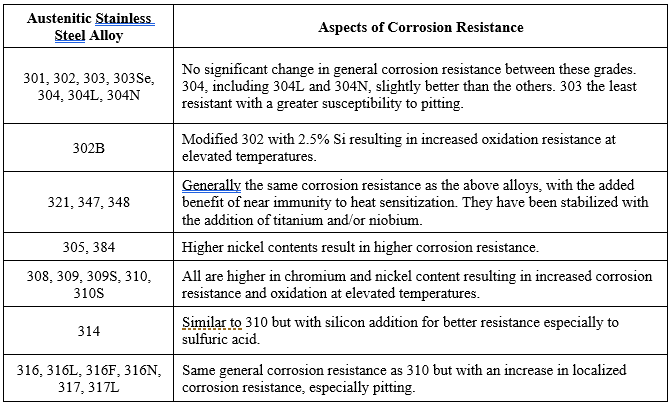

For good quality information please consult reputable reference. One known exception is highly oxidizing acids such as nitric acid to which the molybdenum bearing. The emphasis on corrosion resistance is important due in large part to the varying types of environments in which the end products are used. Under the right or is that wrong circumstances stainless steel alloys can become corroded.

The table below indicates the approximate corrosion resistance of selected corrosion resistant metals to a range of common chemicals. Corrosion resistance table of stainless steel nickel monel inconel. Although stainless steel is widely known for resisting corrosion it isn t completely impervious to corrosion. The information in this chart has been supplied by reputable sources and is to be used only as a guide in selecting equipment for appropriate chemical compatibility.

Check the chemical compatibility of stainless steel with various chemicals solvents alcohols and other products. Other elements such as nickel manganese and molybdenum can be added to enhance stainless steel corrosion resistance. 304 stainless is also cheaper in cost compared to 316 another reason for its popularity and widespread use. Oxidation resistance in stainless steels will increase with additions of chromium silicon and aluminium.

Alloys 316 316l and 317l are more resistant to atmospheric and other mild types of corrosion than the 18 8 stainless steel in general media that do not corrode 18 8 stainless steel tube will not attack these molybdenum containing grades.