314 Stainless Steel Properties

Both aisi 314 stainless steel and aisi 316 stainless steel are iron alloys.

314 stainless steel properties. 314 is the aisi designation for this material. Stainless steel is a group of iron based alloys that contain a minimum of approximately 11 chromium a composition that prevents the iron from rusting as well as providing heat resistant properties. They have 82 of their average alloy composition in common. T 300 series stainless steel.

This data sheet gives you more detailed information about the chemical and mechanical properties and is available as a pdf download. It has a moderately low electrical conductivity among wrought austenitic stainless steels. Grade 310s is a lower carbon version less prone to embrittlement and sensitisation in service. Aisi 314 stainless steel is an austenitic stainless steel formulated for primary forming into wrought products.

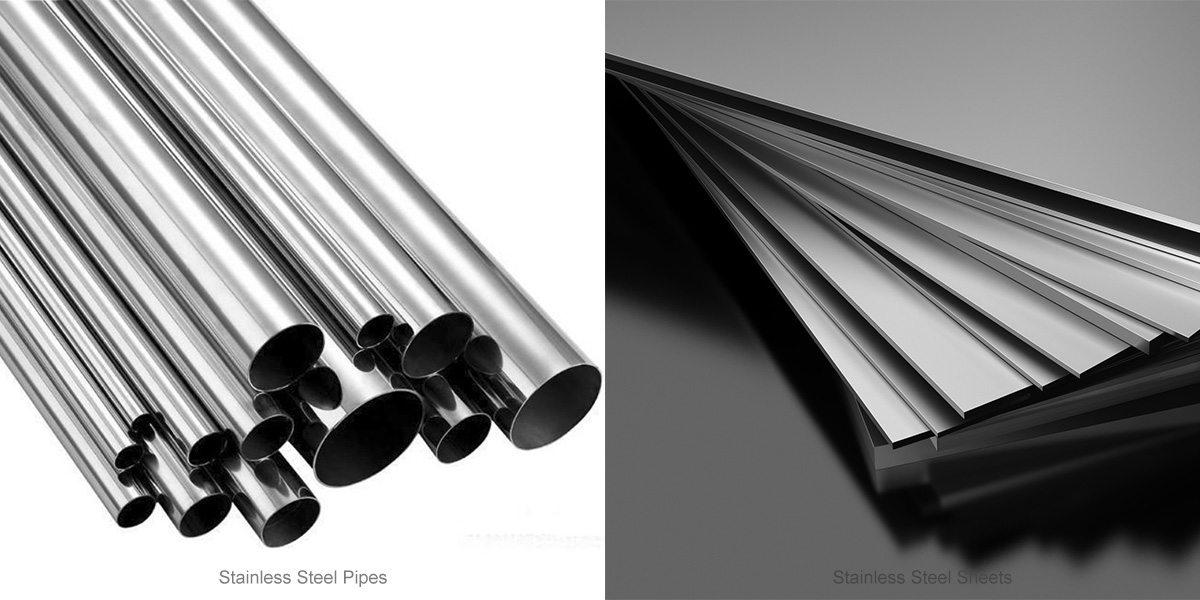

301 physical properties uns designation s30100. Here are the physical and chemical properties of the 301 302 and 304 stainless steel that we regularly stock including the free bend requirements for each alloy. Aisi type 314 stainless steel annealed sheet. S31400 is the uns number.

We supply a vast range in various forms of stainless aluminium and mild steel. There are 34 material properties with values for both materials. Cited properties are appropriate for the annealed condition. The main difference between 304 vs 316 stainless steel is the composition and corrosion resistance ss304 doesn t contain molybdenum while ss316 contains 2 3 molybdenum.

Has the highest heat resisting properties of any chromium nickel steel. The addition of molybdenum provides pitting resistance in phosphoric acid acetic acid and dilute chloride solutions and provides corrosion resistance in sulfurous acid. Properties of grade 310 310s stainless steel these grades contain 25 chromium and 20 nickel making them highly resistant to oxidation and corrosion. Leoscor alloys is a leading manufacturer and distributor of ss 314 sheets which can be hardened only through cold working astm a240 stainless steel 314 sheets is often used in different applications such as in equipment for furnaces annealing and carburizing boxes radiant tubes heat treatment components and more.

Used when maximum resistance to carburization is desired. However it can become very brittle when subjected to prolonged temperatures of 649 816 c 1200 1500 f. The silicon content in this material improves oxidation and carburization resistance.

.gif)