316 Welding Rod Uses

Let s learn in details with uses.

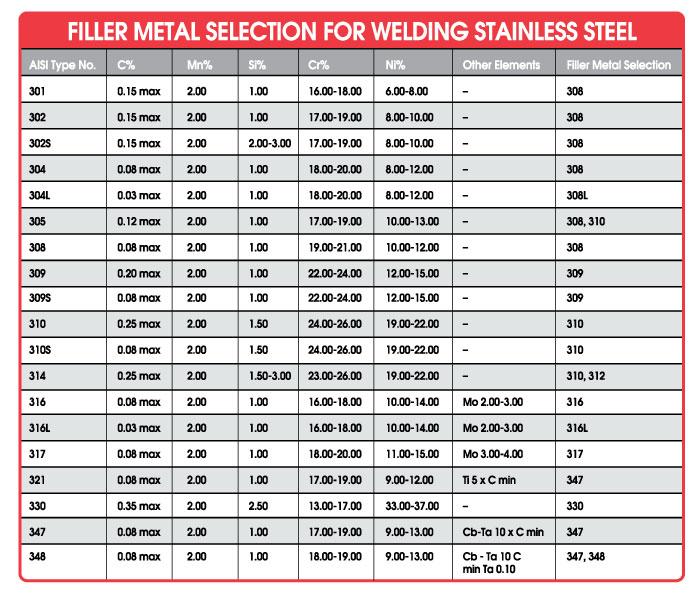

316 welding rod uses. Other uses are welding of hard to weld carbon steels to one another or to stainless steel. Mainly used for welding aisi 316l 317l type stainless steel other uses are in fertilizer plants petrochemical industries chemical plants textile paper pulp paint and dye industries etc. Let s use the good old e6011 arc welding electrode as an example. Excalibur 316 316l 15 16 17 welding positions.

316l also is a great stainless steel for high temperature high corrosion uses which is why it s so popular for use in. Arc welders use a variety of different electrodes also referred to as welding rods. If the wrong welding rod is chosen the weld might not work at all. E electrode sometimes there s er which means either electrode or rod.

So this number is the tensile strength of the material the weld you will create with the rod. Test results for mechanical properties deposit or electrode composition and diffusible hydrogen levels were obtained from a weld produced and tested according to prescribed standards and should not be assumed to be the expected results in a particular application or weldment. Choosing the right welding rod will determine the how easily the weld is performed and how strong the weld will hold. Cf 8m and cf 3m are the cast equivalents of 316 and 316l respectively.

However 316 can be annealed to resist weld decay. Suitable for welding aisi 317 stainless steel. 316l materials have molybdenum in them and the 309l rod does not. For instance it is fine to use them to weld 308 material but not 316 or 316l materials.

The 7018 arc welding rod is commonly used for general purpose welding of carbon steel. 316l including er316lsi filler metal should be used with 316l and 316 base metals. The 309l series of welding rods started about 6 for 1 lb depending upon which type you choose. 60 60 000 pounds per square inch tensile strength.

Welding rods are of different types with the most common welding rod sizes being the 6010 6011 6012 6013 7014 7024 7018. It is a mild steel rod that is coated with a low hydrogen iron based flux compound that vaporizes to shield the molten weld bead from contamination by air and moisture.